MANAGEMENT

PROJECT-MANAGEMENT

The need for a project management

approach is established by the fact that a project will

always tend to increase in size even if its scope is

narrowing. The following four literary laws are applicable

to any project environment:

Parkinson’s law: Work expands to fill the available time or space.

Peter’s principle: People rise to the level of their incompetence.

Murphy’s law: Whatever can go wrong will.

Badiru’s rule: The grass is always greener where you most need it to be dead.

An integrated systems project management approach can help diminish the adverse impacts of these laws through good project planning, organizing, scheduling, and control. The Project Management Institute, as a way of promoting a common language for the practice of project management, developed the Project Management Body of Knowledge (PMBOK), which has been widely adopted around the world. The nine knowledge areas presented in the PMBOK are listed below:

Parkinson’s law: Work expands to fill the available time or space.

Peter’s principle: People rise to the level of their incompetence.

Murphy’s law: Whatever can go wrong will.

Badiru’s rule: The grass is always greener where you most need it to be dead.

An integrated systems project management approach can help diminish the adverse impacts of these laws through good project planning, organizing, scheduling, and control. The Project Management Institute, as a way of promoting a common language for the practice of project management, developed the Project Management Body of Knowledge (PMBOK), which has been widely adopted around the world. The nine knowledge areas presented in the PMBOK are listed below:

MANAGEMENT

RISK MANAGEMENT

Risks are threats. Opportunities are the opposite of

risks and threats. Risks and threats are bad. Opportunities

are good. Risks and threats can never be good. Opportunities

can never be bad. If an Opportunity turns out to be

bad, it wasn't an opportunity, it was misjudged as being

an Opportunity. Opportunities can turn out not be good,

but that does not make them bad. Risks and threats can

turn out to not be bad, but that does not make them

good. In both cases they just did not turn out the way

they were expected. Risks are any uncertain events that

are threats and if they happen they will have negative

impact. Opportunities are any uncertain events that

are not threats and not risks and if they happen they

will have positive impact. Losing or missing an opportunity

is bad but it does not mean the opportunity was bad.

Likewise, finding a risk or opportunity is good but

it does not mean the risk or threat was good.

"Risk Management" is an enhancement tool in business/project management. Risk is inherent in any process (business, production, etc.). Risk Management addresses all of the items (events - seen and unseen) that will/can/may have an impact. View the handling of these matters as calculating Risk/Reward payoffs. In other words, every "Risk" has a component of outcome that must be determined by "value", or desirability to the process. This is where you come up with the "Positive or Negative" notion regarding risks. Identify EVERY risk, assess its potential impact and create a plan to address its contingency. In the end, "Take a Calculated Risk", meaning, consider the potential risk (Risk - by definition) and have determined that the course of action will allow you to navigate that risk successfully through mitigation. (Reward - Opportunity). EVERY Business/Project is faced with risk. "Risk Management" is a STRATEGIC and TACTICAL process for business or project management that is dynamic and adaptable to any given scenario or circumstance.

"Risk Management" is an enhancement tool in business/project management. Risk is inherent in any process (business, production, etc.). Risk Management addresses all of the items (events - seen and unseen) that will/can/may have an impact. View the handling of these matters as calculating Risk/Reward payoffs. In other words, every "Risk" has a component of outcome that must be determined by "value", or desirability to the process. This is where you come up with the "Positive or Negative" notion regarding risks. Identify EVERY risk, assess its potential impact and create a plan to address its contingency. In the end, "Take a Calculated Risk", meaning, consider the potential risk (Risk - by definition) and have determined that the course of action will allow you to navigate that risk successfully through mitigation. (Reward - Opportunity). EVERY Business/Project is faced with risk. "Risk Management" is a STRATEGIC and TACTICAL process for business or project management that is dynamic and adaptable to any given scenario or circumstance.

MANAGEMENT

PROJECT PROGRAM MANAGEMENT

Project Managers manage projects and Program Managers

manage a portfolio of projects. The nescience led to

the myth that Program Management is glorified Project

Management, but there are 5 fundamental differences

between the roles:

1. Programs are ongoing, Projects end

2. Programs are tied to the companies' financial forcasting

3. Program Managemernt is Governance incentive

4. Programs have a greater scope of financial management

5. Program change management requires Executive Leadership skills.

1. Programs are ongoing, Projects end

2. Programs are tied to the companies' financial forcasting

3. Program Managemernt is Governance incentive

4. Programs have a greater scope of financial management

5. Program change management requires Executive Leadership skills.

MANAGEMENT

EMERGENCY MANAGEMENT

Emergency management is the creation of plans through

which businesses reduce vulnerability to hazards and

cope with disasters. Emergency management does not avert

or eliminate the threats, instead it focuses on creating

plans to decrease the IMPACT of disasters. Failure to

create a plan could lead to damage to assets, human

mortality, and lost revenue. Currently over 60% of the

businesses worldwide do not have emergency management

plans. The steps presented in the picture speaks for

themselves, however recently another step is added to

Emergency Management, Prevention!

The system can be easily extended for lower level like Project Management. For example, a Project Manager turns out not have the required skills for the job. This will be the disaster. The business has to respond, recover by replacement etc. etc. We as DGL Global Services Ltd can help you with Emergency Management on Project Management level, our direct approach is well appreciated in the near past on many projects! The link to Interim Management is very close in this case.

The system can be easily extended for lower level like Project Management. For example, a Project Manager turns out not have the required skills for the job. This will be the disaster. The business has to respond, recover by replacement etc. etc. We as DGL Global Services Ltd can help you with Emergency Management on Project Management level, our direct approach is well appreciated in the near past on many projects! The link to Interim Management is very close in this case.

MANAGEMENT

INTERIM MANAGEMENT

Interim managers are experienced executives with specialist

skills and a track record of achievement, often hired

by businesses on a project basis to solve problems.

Interim managers can fill gaps, replace people or take

on strategic roles and deliver results quickly before

moving on to the next assignment. An increasing number

of business leaders are seeing interim managers as a

more cost-effective solution than management consultants.

DGL Global Services Ltd has a proven track record of

Interim management where previous project managers and

site managers were failing.

MANAGEMENT

INTERFACE MANAGEMENT

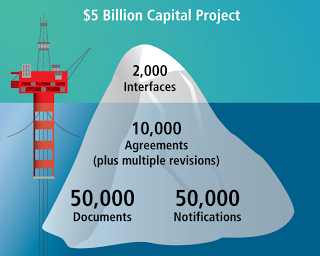

The objective of the interface management process is

to guarantee the proper functioning of a system (read

project) composed of many interfacing sub-systems (read

tasks, responsibilities and disciplines on project level).

Ineffective interface management is often responsible

for the failure of large systems development projects;

interface mismatches causing delays in commissioning

and excessive re-work. Interface integrity is particularly

important with projects involving stringent safety and

security requirements. The existence of multiple interfaces

is a risk raiser in the management of a systems integration

project. This risk is managed by following a pre-planned

interface management plan. An Interface Management Plan

(IMP) formalizes an agreement between two or more stakeholders,

contractors and vendors that are developing interfacing

components of a project. An Interface Management Plan

addresses the following issues:

1. Identification of the sub-systems or sub-system components that require interfacing

2. Assignment of responsibility and authority for interface management

3. Specification of the information to be exchanged over the interface with references to Interface Control Documents

4. Identification of the interface requirements including the scope of works, design, development, installation, testing and commissioning of the sub-systems

5. Indication of requirements for coordination of facilities associated with the interface

6. The technical strategy for developing, testing and deploying the interface including specification of the requirements, design and testing documentation required

7. Establishment of development schedules and resources required including the relationship between interface development milestones and overall project milestones

8. Specification of the management and technical skills required for the associated development work, at each phase of the developers' project life cycles

9. Quality Management procedures relevant to interface development including identification of major reviews

Interface Management is often underestimated in a project and therefor causing a lot of issues during project execution since interfacrs are not clear (who is responsible, who to talk to, who is going to take action). A decent Interface Management Plan shall be a guide for the entire project management and project execution from A to Z and in place from start of the project. DGL Global Services Ltd has experience with creating an IMP to help you run the project more smootly.

1. Identification of the sub-systems or sub-system components that require interfacing

2. Assignment of responsibility and authority for interface management

3. Specification of the information to be exchanged over the interface with references to Interface Control Documents

4. Identification of the interface requirements including the scope of works, design, development, installation, testing and commissioning of the sub-systems

5. Indication of requirements for coordination of facilities associated with the interface

6. The technical strategy for developing, testing and deploying the interface including specification of the requirements, design and testing documentation required

7. Establishment of development schedules and resources required including the relationship between interface development milestones and overall project milestones

8. Specification of the management and technical skills required for the associated development work, at each phase of the developers' project life cycles

9. Quality Management procedures relevant to interface development including identification of major reviews

Interface Management is often underestimated in a project and therefor causing a lot of issues during project execution since interfacrs are not clear (who is responsible, who to talk to, who is going to take action). A decent Interface Management Plan shall be a guide for the entire project management and project execution from A to Z and in place from start of the project. DGL Global Services Ltd has experience with creating an IMP to help you run the project more smootly.

INTERIM SOLUTIONS

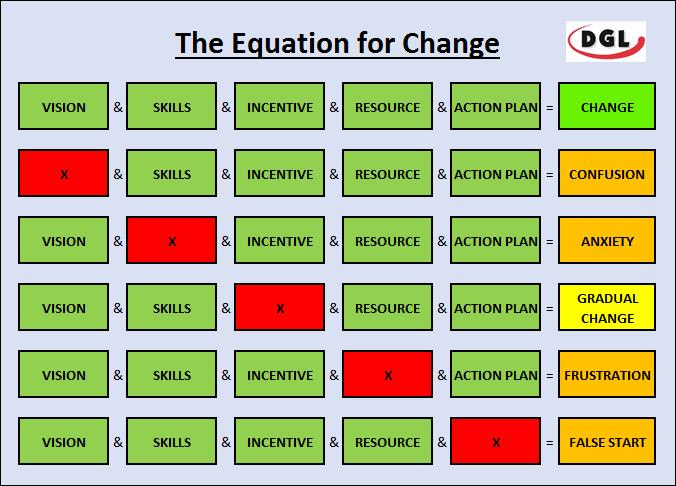

EQUATION OF CHANGE

The presented Equation of Change shall be used as a

common tool and can be extended with project specific

needs like financial items, human factors etc., to define

the Equation Of Change for a specific project.

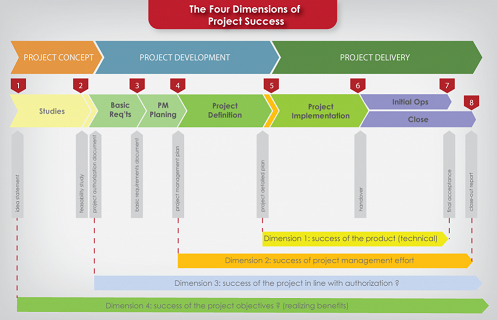

SUPPORT

MEASUREMENT OF SUCCESS

The DGL Services Ltd general approach of Measurement

of Project Success. By adding several measurement points

into the dimensions, (like execution time and financial

benefits to Dimension 4) and connecting weight factors

to each measument point, a total measurement of project

success can be generated. There are ofcourse different

approaches to measure the success, we like to share

ours...

ENGINEERING

FEASIBILITY STUDIES

A good Feasibility Study helps to objectively decide

whether to proceed with a proposed project. A Feasibility

Study should have broad considerations when considering

whether to undertake a new project. It should consider

things such as technological limitations, the marketplace,

your marketing strategy, staffing requirements, schedule

and financial projections and provides a recommendation

of which plan to implement:

ECONOMIC FEASIBILITY:

An economic feasibility study reports on the cost factors of a proposed plan to an organization.

OPERATIONAL FEASIBILITY:

An operational feasibility report focuses on the effectiveness of the function of the operations of an organization.

MARKET FEASIBILITY:

A market feasibility study helps determine if your location is beneficial to your business.

TECHNICAL FEASIBILITY:

The technical feasibility study identifies a number potential challenges and problems that you may encounter technically based on the requirements and goals of the business. The study also identifies technical options based on the business's resources and requirements wih a final recommendation.

ECONOMIC FEASIBILITY:

An economic feasibility study reports on the cost factors of a proposed plan to an organization.

OPERATIONAL FEASIBILITY:

An operational feasibility report focuses on the effectiveness of the function of the operations of an organization.

MARKET FEASIBILITY:

A market feasibility study helps determine if your location is beneficial to your business.

TECHNICAL FEASIBILITY:

The technical feasibility study identifies a number potential challenges and problems that you may encounter technically based on the requirements and goals of the business. The study also identifies technical options based on the business's resources and requirements wih a final recommendation.

ENGINEERING

FEED

FEED stands for Front End Engineering Design. The FEED

is basic engineering and is the follow up of the Feasibility

study. The FEED design describes the technical requirements

as well as rough investment cost for the project The

FEED package is used as the basis for bidding the Execution

Phase Contracts (EPC, EPCI, etc) and is tyically followed

by Detailed Engineering.

A good FEED will reflect all the clients project specific requirements and avoid significant changes during the detailed design and execution phase. During the FEED phase there shall be close communication between all shareholders to define1 the project specific requirements. The amount of time invested in Front-End Engineering is higher than a traditional quote, because project specifications are thoroughly extracted and the following typically developed in detail:

► Project Organization Chart

► Project Scope (design package, HAZOP, equipment layouts, automation strategy etc.)

► PFD’s

► Project timeline

► Fixed-bid quote

A good FEED will reflect all the clients project specific requirements and avoid significant changes during the detailed design and execution phase. During the FEED phase there shall be close communication between all shareholders to define1 the project specific requirements. The amount of time invested in Front-End Engineering is higher than a traditional quote, because project specifications are thoroughly extracted and the following typically developed in detail:

► Project Organization Chart

► Project Scope (design package, HAZOP, equipment layouts, automation strategy etc.)

► PFD’s

► Project timeline

► Fixed-bid quote

ENGINEERING

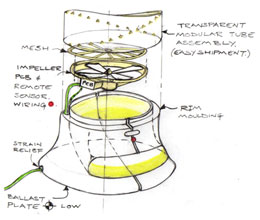

CONCEPTUAL DESIGN

Maximizing innovation in new project requires an investment

in conceptual design. Technological advances have streamlined

project development, reducing the design cycles, controlling

the costs, and improving the quality.

Conceptual design - creating the innovative concepts that will pay the efforts down the road - is a decidedly different undertaking, with its own needs, challenges, and objectives. The endpoint of conceptual design is to discover innovation, transforming new ideas and solutions into workable concepts for future development.

Conceptual design requires different workflows and approaches to be effective. Conceptual design focuses on concepts instead of details, and requires collaboration and communication with all stakeholders during conceptualization, rather than precise communication and documentation with downstream departments after a design is already established.

Conceptual design engineers explore the “what if” rather than the “what is” and investigate how to design an innovative concept rather than how to fix the problem. These distinctly different workflows, challenges, and goals require a design solution that’s tailored specifically to conceptual design.

Conceptual design - creating the innovative concepts that will pay the efforts down the road - is a decidedly different undertaking, with its own needs, challenges, and objectives. The endpoint of conceptual design is to discover innovation, transforming new ideas and solutions into workable concepts for future development.

Conceptual design requires different workflows and approaches to be effective. Conceptual design focuses on concepts instead of details, and requires collaboration and communication with all stakeholders during conceptualization, rather than precise communication and documentation with downstream departments after a design is already established.

Conceptual design engineers explore the “what if” rather than the “what is” and investigate how to design an innovative concept rather than how to fix the problem. These distinctly different workflows, challenges, and goals require a design solution that’s tailored specifically to conceptual design.

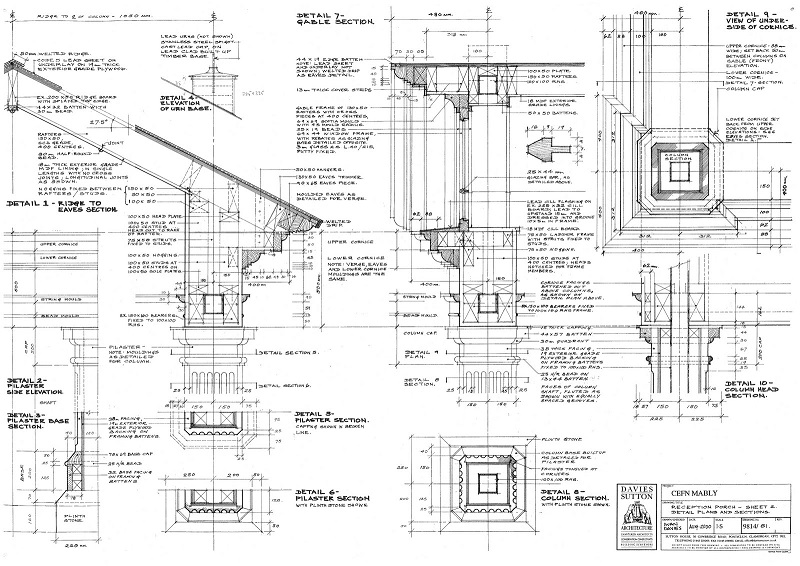

ENGINEERING

DETAILED DESIGN

Detailed design is in fact a decision making process

in which mathematics, basic sciences and engineering

sciences are applied to convert resources optimally

to meet a stated objective.

Among the fundamental elements of the design process are the establishment of objectives and criteria, synthesis, analysis, construction, testing and evaluation as defined in the previous FEED or Conceptual design. During Detailed design, the design team uses both the Requirements Specification and the Architectural Specification provided by the previous Conceptual design or FEED phase to develop a detailed design of the system (not every company is using the Conceptual design phase but will use the FEED phase instead). This design will provide a detailed specification for each component, thoroughly describing interfaces and functions provided by each component This detailed design will serve as the basis for the final implementation after Approved For Construction (AFC).

Among the fundamental elements of the design process are the establishment of objectives and criteria, synthesis, analysis, construction, testing and evaluation as defined in the previous FEED or Conceptual design. During Detailed design, the design team uses both the Requirements Specification and the Architectural Specification provided by the previous Conceptual design or FEED phase to develop a detailed design of the system (not every company is using the Conceptual design phase but will use the FEED phase instead). This design will provide a detailed specification for each component, thoroughly describing interfaces and functions provided by each component This detailed design will serve as the basis for the final implementation after Approved For Construction (AFC).

ENGINEERING

AS-BUILT SERVICES

Generating a reliable As-built package ready to be handed

over to Operations, Maintenance and Asset is a page

by page action. In other words, every deliverable from

the Detailed design has to be updated to represent the

actual situation in the field. This means that all modifications

produced during the execution of the project like redline

drafting or so called Red Line Mark Ups (RLMU) shall

be processed and updated in the original document(s)

and drawing(s) accordingly:

REDLINE DRAFTING:

- Updates to layout drawings based on redline markups with isometrics, instrument location etc.

- Updates to PFD's based on redline markups

- Complete skid/building details based on redline markups

- Instrumentation from P&ID’s:- Data gathering to complete the documentation for SAP

ACQUISITIONS:

- Collect latest revisions of drawings and documents from all contractors to verify the final revision

- Implement the redline markups to generate the as-built

- Update the drawings of acquisitions to match your inhouse formatting and layout standards

FIELD CHANGES:

- Submit field changes to the original approved design AN up-to-date As-built has a lot of business benefits:

- Improve Safety

- Reduce Project Rework and Subsequent Delays

- Improve Management of Change

- Manage Legal Rights of Way

- Support for Compliance and Safety Audits

- Shorten Turnarounds and Shutdowns

etc. etc.

REDLINE DRAFTING:

- Updates to layout drawings based on redline markups with isometrics, instrument location etc.

- Updates to PFD's based on redline markups

- Complete skid/building details based on redline markups

- Instrumentation from P&ID’s:- Data gathering to complete the documentation for SAP

ACQUISITIONS:

- Collect latest revisions of drawings and documents from all contractors to verify the final revision

- Implement the redline markups to generate the as-built

- Update the drawings of acquisitions to match your inhouse formatting and layout standards

FIELD CHANGES:

- Submit field changes to the original approved design AN up-to-date As-built has a lot of business benefits:

- Improve Safety

- Reduce Project Rework and Subsequent Delays

- Improve Management of Change

- Manage Legal Rights of Way

- Support for Compliance and Safety Audits

- Shorten Turnarounds and Shutdowns

etc. etc.

- The contractor failed to handover a final and/or reliable As-built

- The internal Document Control Management procedure is not working optimally

- Other departments like Maintenance and Operations are not updating the As-built after a inhouse modification

- etc.

DGL Global Services Ltd can help you to generate a reliable As-built based on all the above and help you to maintain the As-built after every change.

EXECUTION

(PRE)COMMISSIONING & MIGRATION PLAN

COMMISSIONING is providing the integral connection between design, build and operational systems for asset information management.

Commissioning encompasses testing, calibration and certification of the facility and its systems,

including the hardware, software and networks that will operate within the production environment.

The activities noted in a Commissioning Plan (like the dynamics of the project, identifying hold points, decision-to-proceed points and go/no-go criteria) ensure that all aspects of the asset operate to the specification and are fit for performance.

As part of that process, document management and plant maintenance systems are validate and the information residing in those systems is verified.

PRECOMMISSIONING is the actual installation activity and shall not be confused with COMMISSIONING!

MIGRATION involves moving content from an unmanaged state to an existing management system. Migration takes place when the plant is already operational, so the process takes several steps. A Migration Plan includes the migration from the project team to the individual or group responsible for ongoing operation of the product. This section should provide a detailed description of both the implementation steps, migration steps from project team to operation team, as well as the specific requirements and responsibilities of all involved. DGL Global Services Ltd can help you to run these processes smoothly to prevent poorly managed information hand over and loss of captial project expenditure.

PRECOMMISSIONING is the actual installation activity and shall not be confused with COMMISSIONING!

MIGRATION involves moving content from an unmanaged state to an existing management system. Migration takes place when the plant is already operational, so the process takes several steps. A Migration Plan includes the migration from the project team to the individual or group responsible for ongoing operation of the product. This section should provide a detailed description of both the implementation steps, migration steps from project team to operation team, as well as the specific requirements and responsibilities of all involved. DGL Global Services Ltd can help you to run these processes smoothly to prevent poorly managed information hand over and loss of captial project expenditure.

EXECUTION

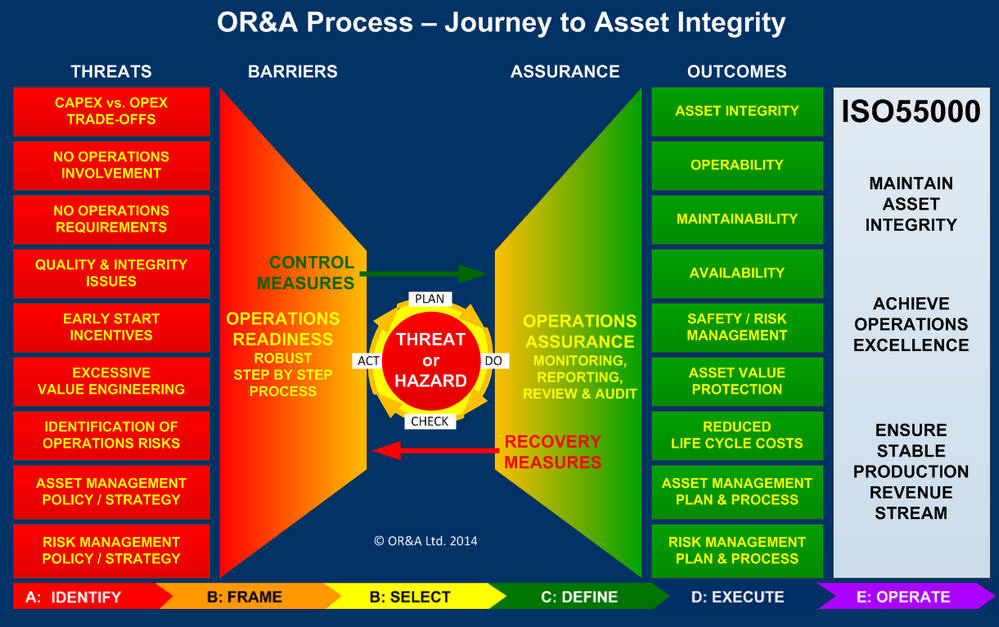

OPERATIONS READINESS & ASSURANCE

OPERATIONS READINESS is the process of preparing the custodians of an asset that at the point of handover, the organisation is fully prepared to take ownership of the asset.

ASSURANCE refers to the various stakeholders in a project that both their asset and supporting organisation will be in a state of Readiness to Operate. First of all, it is essential to understand what is required for the OR&A system before setting up the basic structure. The key values for setting up the basic structure are directives, regulations, rules, processes, instructions, best practices, lessons learned, normaitive and legislative requirements etc.

The target values are for example the operation requirements like the operability, maintainability and availability of the asset. The entire excersise is a significant undertaking and shall be done by experienced and qualified OR&A engineers. Once done, the process can be re-used over and over again on every project the company is executing. DGL Global Services Ltd can provide the knowledge and experience to set up a working OR&A structure for your project.

ASSURANCE refers to the various stakeholders in a project that both their asset and supporting organisation will be in a state of Readiness to Operate. First of all, it is essential to understand what is required for the OR&A system before setting up the basic structure. The key values for setting up the basic structure are directives, regulations, rules, processes, instructions, best practices, lessons learned, normaitive and legislative requirements etc.

The target values are for example the operation requirements like the operability, maintainability and availability of the asset. The entire excersise is a significant undertaking and shall be done by experienced and qualified OR&A engineers. Once done, the process can be re-used over and over again on every project the company is executing. DGL Global Services Ltd can provide the knowledge and experience to set up a working OR&A structure for your project.

EXECUTION

COMPLETION

A proper hand over of the project on COMPLETION is a key aspect of Construction Project Management.

Completion is to ensure that the dry run after commissioning of the various systems meet the required performance parameters and all glitches are smoothened. The focus is on the pre-delivery inspection punch lists and proper removal of defects.

The Contractor prepares a set of checklists (Inspection and Test Reports or ITRs) that encompass civil, electrical, instrumental, HVAC, process, etc. to ensure to meet the exact working requirements of the clients. The Contractor provides adequate documented checkpoints and advisory notes for smooth operation and maintenance of the asset, including the redline markup drawings or As-build drawings, manuals, the necessary certificates and approvals, as part of the hand over package, this all in preparation of a Completion Certificate towards the Contractor on successful hand over of the project.

Completion is to ensure that the dry run after commissioning of the various systems meet the required performance parameters and all glitches are smoothened. The focus is on the pre-delivery inspection punch lists and proper removal of defects.

The Contractor prepares a set of checklists (Inspection and Test Reports or ITRs) that encompass civil, electrical, instrumental, HVAC, process, etc. to ensure to meet the exact working requirements of the clients. The Contractor provides adequate documented checkpoints and advisory notes for smooth operation and maintenance of the asset, including the redline markup drawings or As-build drawings, manuals, the necessary certificates and approvals, as part of the hand over package, this all in preparation of a Completion Certificate towards the Contractor on successful hand over of the project.

EXECUTION

WORK PACKAGES, JHA & PTW

WORK PACKAGES (WP), JOB HAZARD ANALYSIS (JHA), PERMITS TO WORK (PTW)... all documents we require upfront to do actual job activities in the field.

A WORK PACKAGE is a part of a project that can be assigned to a specific task for execution. A Work package is presenting a brief Activity Description, Drawings and Documentation, Activity Resources of Skill and Expertise, Activity Estimates of Effort and Duration, Activity Schedule, Activity Risks and recommended (special) tools & equipment. Work Packages are assigned a Work Authorization or Control Account. Estimates of finalized work packages are used to calculate the actual progress against the planned progress. Progress made in the work package is used to calculate the earned value.

A JOB HAZARD ANALYSIS provides a documented mechanism to answer the question “How do I know that I’m doing my job safe?” It is a methodical analysis tool used to identify and eliminate workplace hazards before they can cause harm. It makes common sense that the HSE department is involved to prepare or evaluate the JHA before an actual job will take place. The JHA shall be part of every WP.

A PERMIT TO WORK is a formal management system (software) used to control (high) risk activities. The intention of the permit to work is to:

- Ensure that the intended work to take place is properly authorised

- Clarify the nature and extent of the work

- Specify which precautions must be taken and which activities are prohibited

- Indicate the date, time and location that the specified activities may occur

- Ensure awareness to others of the activity in a certain area

- Provide a record of the work done.

All these documents are required upfront before an activity can take place at all. Besides the 'paperwork', qualified personnel like site supervisors, HSE officers, site manager etc. shall be aware and present to verify if the permit is followed, no unsafe actions are present etc. All issues shall be reported back to the team to update the WP, JHA and Lessons Learned.

A WORK PACKAGE is a part of a project that can be assigned to a specific task for execution. A Work package is presenting a brief Activity Description, Drawings and Documentation, Activity Resources of Skill and Expertise, Activity Estimates of Effort and Duration, Activity Schedule, Activity Risks and recommended (special) tools & equipment. Work Packages are assigned a Work Authorization or Control Account. Estimates of finalized work packages are used to calculate the actual progress against the planned progress. Progress made in the work package is used to calculate the earned value.

A JOB HAZARD ANALYSIS provides a documented mechanism to answer the question “How do I know that I’m doing my job safe?” It is a methodical analysis tool used to identify and eliminate workplace hazards before they can cause harm. It makes common sense that the HSE department is involved to prepare or evaluate the JHA before an actual job will take place. The JHA shall be part of every WP.

A PERMIT TO WORK is a formal management system (software) used to control (high) risk activities. The intention of the permit to work is to:

- Ensure that the intended work to take place is properly authorised

- Clarify the nature and extent of the work

- Specify which precautions must be taken and which activities are prohibited

- Indicate the date, time and location that the specified activities may occur

- Ensure awareness to others of the activity in a certain area

- Provide a record of the work done.

All these documents are required upfront before an activity can take place at all. Besides the 'paperwork', qualified personnel like site supervisors, HSE officers, site manager etc. shall be aware and present to verify if the permit is followed, no unsafe actions are present etc. All issues shall be reported back to the team to update the WP, JHA and Lessons Learned.

EXECUTION

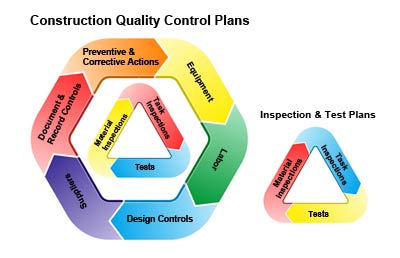

METHOD STATEMENT - INSPECTION & TEST PLAN

A

METHOD STATEMENT (MS) is a document detailing HOW a particular task or activity will be carried out.

It shall detail the possible dangers/risks associated with the particular part of the project and the methods of control to be established to show how the work will be managed safely.

A MS is prepared together with an Inspection & Test Plan and can replace the WP and JHA (pending company guidelines).

An INSPECTION & TEST PLAN (ITP) is the program of inspection, testing of materials and reporting the results and part of the Construction Quality Control Plan. An ITP is made and issued by the Quality Engineer, reviewed by the Quality Manager, Construction Manager and approved by Project Manager before it shall be submitted to the Engineer. The QA/QC Engineer shall maintain a register of all Inspection and Test Plan (ITP) including Checklists. Many software tools and templates are available for preparation of ITPs.

An ITP is not to be confused with a FACTORY ACCEPTANCE TEST (FAT), a SITE ACCEPTANCE TEST (SAT) or any other test but shall be part of it for a good Quality Control management. Before equipment shall be accepted, another ITP is necessary to hand over to asset.

An INSPECTION & TEST PLAN (ITP) is the program of inspection, testing of materials and reporting the results and part of the Construction Quality Control Plan. An ITP is made and issued by the Quality Engineer, reviewed by the Quality Manager, Construction Manager and approved by Project Manager before it shall be submitted to the Engineer. The QA/QC Engineer shall maintain a register of all Inspection and Test Plan (ITP) including Checklists. Many software tools and templates are available for preparation of ITPs.

An ITP is not to be confused with a FACTORY ACCEPTANCE TEST (FAT), a SITE ACCEPTANCE TEST (SAT) or any other test but shall be part of it for a good Quality Control management. Before equipment shall be accepted, another ITP is necessary to hand over to asset.

EXECUTION

FINAL HAND OVER

The FINAL HAND OVER is the final contractual milestone and very last stage of any project. It’s the point at which the client officially takes ownership of the project.

All open punchlists are resolved, drawings and documentation are As-Build, test certificates are ready, Mechanical Completion Certificates and Project Completion Certificates are signed and so on.

The OR&A is fully completed so the project is ready to be handed over to the asset owner.

The term for warranty is normally not connected to the Final Hand Over date since projects can be running for many years and parts of the asset were handed over in an earlier stage. The project is finished and a full evaluation of the entire project shall take place on both sides:

- What are the Lessons Learned from this project?

- What can we do better next time?

- How can we prevent to make the same mistakes again?

etc. etc.

The term for warranty is normally not connected to the Final Hand Over date since projects can be running for many years and parts of the asset were handed over in an earlier stage. The project is finished and a full evaluation of the entire project shall take place on both sides:

- What are the Lessons Learned from this project?

- What can we do better next time?

- How can we prevent to make the same mistakes again?

etc. etc.

Our Services

DGL Global Services Ltd is specialized in filling the gaps in

your projects with additional high level skilled manpower. Feasibility

studies, Scope of Work, Conceptual design, Detailed design,

Engineering, Second Opinion, Project Management, Construction

Management and Execution, Support, Interim Solutions, you name

it and we can do it! Many customers preceded you already by

submitting their problems to us with the knowledge we are capable

to solve it. This is the way we prefer to operate in the market,

not by advertising and selling hours and knowledge but by helping

our customers. We will get rewarded for our intentions. Do you

believe our service is expensive? Wait until you hire someone

else to find out who is more expensive in the end...

MANAGEMENT

Management is not just one task,

it is a compilation of many different tasks and disciplines.

Below are a few examples out of many possible disciplines:

Management is not just one task,

it is a compilation of many different tasks and disciplines.

Below are a few examples out of many possible disciplines:-

►Project Management

►RISK Management

►Project Program Management

►Emergency Management

►Interim Management

►Interface Management

The (senior) project manager is a person with the correct skill set and passion for the task and is accountable for accomplishing the stated project. The project manager shall be capable to lead a team of qualified members to accomplish the task using the tools available for the job. The project manager shall have the vision, skills, incentive, recourses and an action plan to make a change!

ENGINEERING

"Scientists investigate that

which already is; Engineers create that which never been."

Albert Einstein hit the nail right on the head when he pondered

the question "What is engineering?". Engineers are shaping

the future by applying their skills to almost everything

you can think of, from medicine to renewable energy, food

technologies to sustainable mining. There is no limit to

what engineers can do, the limit is the creativity and inventivity

of the engineer and the will to explore new technologies

to move the current barriers.

"Scientists investigate that

which already is; Engineers create that which never been."

Albert Einstein hit the nail right on the head when he pondered

the question "What is engineering?". Engineers are shaping

the future by applying their skills to almost everything

you can think of, from medicine to renewable energy, food

technologies to sustainable mining. There is no limit to

what engineers can do, the limit is the creativity and inventivity

of the engineer and the will to explore new technologies

to move the current barriers.Our expertise is, but not limited to:

►Feasibility studies

►FEED

►Conceptual design

►Detailed design

►As-Built services

EXECUTION

A smooth execution of a project

depends on many parameters which are changing on a daily

basis. This doesn't mean the schedule, goals etc. shall

be extended automatically, we try to stay to the original

plan! The approach for a Greenfield (EPCM) project (new development

area) and a Brownfield (EPCM) project (interference in an

existing area) is different however. Especially for Brownfield

projects, a detailed migration plan is essential. Below

is a possible breakdown of the general phases in execution:

A smooth execution of a project

depends on many parameters which are changing on a daily

basis. This doesn't mean the schedule, goals etc. shall

be extended automatically, we try to stay to the original

plan! The approach for a Greenfield (EPCM) project (new development

area) and a Brownfield (EPCM) project (interference in an

existing area) is different however. Especially for Brownfield

projects, a detailed migration plan is essential. Below

is a possible breakdown of the general phases in execution:►(Pre-)Commissioning & Migration

►Operation Readiness & Assurance

►Completion strategy

►Work packages, JHA & PTW

►MS, Inspection & Test Plans

►Final Hand over dossier

SECOND OPINION

As project team, it is difficult

to take distance of the task to complete and question yourself

"are we doing the right thing in the most convenient way?".

The input, knowledge and ideas from a third party can be

very refreshing, especially when risks are overlooked by

the team because their focus is to implement their own ideas.

This risk is significant when vendors are part of the project

scope.

As project team, it is difficult

to take distance of the task to complete and question yourself

"are we doing the right thing in the most convenient way?".

The input, knowledge and ideas from a third party can be

very refreshing, especially when risks are overlooked by

the team because their focus is to implement their own ideas.

This risk is significant when vendors are part of the project

scope.To quote Abraham Lincoln, "I know you believe you understand what you think I said, but I am not sure you realize that what you heard is not what I meant." Advantage is taken at tendering stage since bidders take into account scope changes of up to 20% of the original scope. The worst thing is that even clients are accepting this margin just as a fact. By asking for a second opinion, the scope costs can often be reduced by the same percentage!

INTERIM SOLUTIONS

Despite the care taken in selection

procedures by highly qualified agencies, practise is that

not eveyone suits for the role selected for many reasons.

After all we are human beings, not robots! What next? An

interim solution is needed to create the necessary change,

however in case of contracting, interim often turns into

a final replacement if the right person is found. Weekly

or monthly measurement is necessary to determine if the

equation of change is still valid:

Despite the care taken in selection

procedures by highly qualified agencies, practise is that

not eveyone suits for the role selected for many reasons.

After all we are human beings, not robots! What next? An

interim solution is needed to create the necessary change,

however in case of contracting, interim often turns into

a final replacement if the right person is found. Weekly

or monthly measurement is necessary to determine if the

equation of change is still valid: - Do we have the right vision?

- Do we have the right skills?

- Do we have the right incentives?

- Do we have the right recourses?

- Do we have the right action plan?

If one of the sources is out of range, adjustment is necessary to keep the project on track, failure leads to unwanted risks as shown in the

SUPPORT

Every company and every individual

is able to deliver support and advice in the broadest sense.

But to get support and advice of high quality which really

makes an impact, that is another story! But why do you need

Support at all from DGL Global Services Ltd? To make a project

to a success! But when is a project a success, how do we

measure it without just an indivivual point of view? We

can measure following to determine if a project was successful:

Every company and every individual

is able to deliver support and advice in the broadest sense.

But to get support and advice of high quality which really

makes an impact, that is another story! But why do you need

Support at all from DGL Global Services Ltd? To make a project

to a success! But when is a project a success, how do we

measure it without just an indivivual point of view? We

can measure following to determine if a project was successful:1. Technical success of the project

2. Project Management success

3. Project Delivery success

4. Project Outcome success

These are the four dimensions to measure if a project was successful or not without personal opinions of stakeholders as shown in the